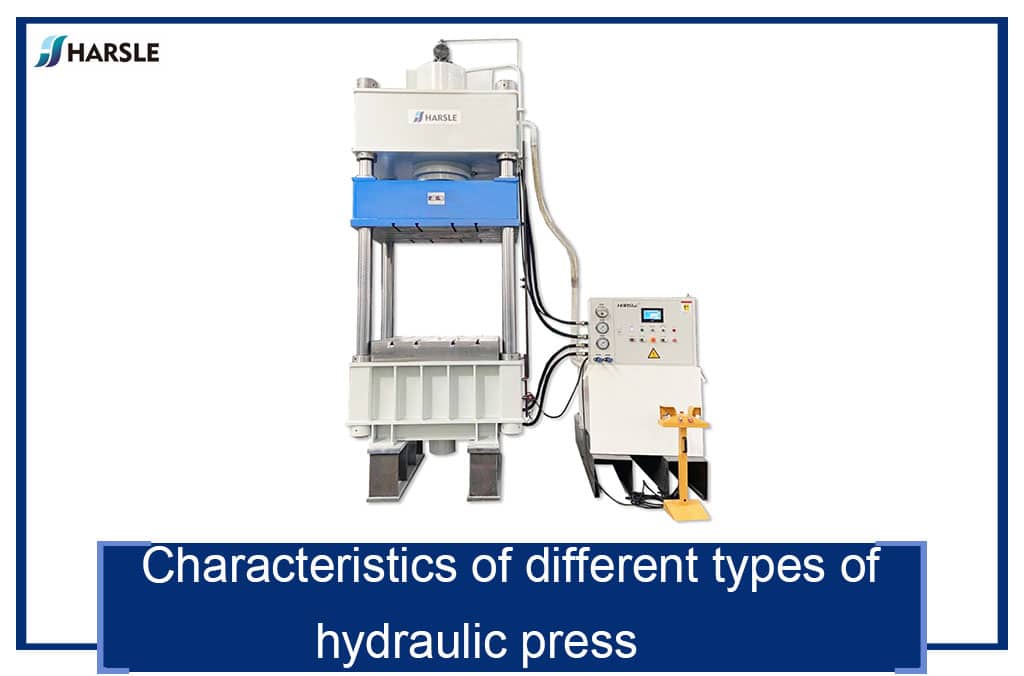

Кратко представьте несколько характеристик гидравлического пресса.

1.600 ton press, Based on the principle of hydraulic transmission, the actuator structure is simple, and the structure is easy to achieve a large working pressure, a large working space and a long working stroke, so it has strong adaptability and is convenient for pressing large workpieces or longer and higher Artifact. To

2. Due to the simple structure of the actuator and the characteristics of flexible arrangement, it can be arranged in multiple directions and distributed in multiple locations according to the process requirements. To

3. The rated maximum pressure of the hydraulic press can be generated at any position of the stroke. The pressure can be maintained for a long time at the lower switching point, which is very necessary for many processes.

4. 600 ton press,The total stroke of the movable beam can be changed steplessly within a certain range, and the down conversion point of the stroke can also be conveniently controlled or changed according to the process requirements. To

5. The speed of the movable beam can be adjusted to a considerable extent within a certain range, so as to adapt to the different requirements of the slider speed in the process. When the pump is used for direct transmission, the adjustment of the slider speed has nothing to do with the pressure and stroke. To

6. 600 ton press,The combination of different valves can be used to realize different procedures of the process, which can easily adapt to the changes of the procedures, and facilitate the realization of program control valves and computer automatic control. To

7. A simple method can be used to adjust or limit the pressure in a working cycle, with good safety performance and not easy to overload, which is beneficial to protect the mold. To

8. Work smoothly. The impact, vibration and noise are small, and the shearing machine manufacturers have great benefits to the health of workers, the foundation of the plant, the surrounding environment and the equipment itself. To

9. The working stroke speed is relatively slow, and the number of working cycles per minute is not easy to increase. This was originally the weakness of hydraulic machines, but this year, with the emergence of high-power, high-speed, high-pressure hydraulic pumps, the rapid performance of hydraulic machines has been greatly improved.

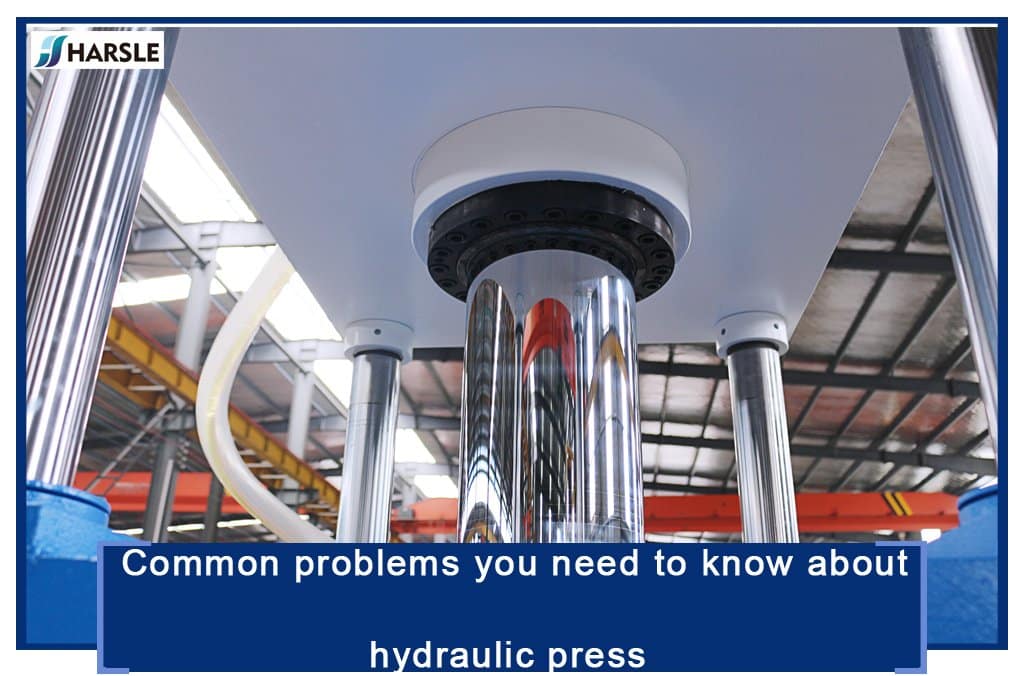

How to wash the hydraulic press?

1. During the cleaning process, the operation of the hydraulic pump and the heating of the cleaning medium are performed simultaneously. When the temperature of the cleaning oil is (50-80)℃, the rubber residue in the system is easy to remove;

2. When cleaning the general hydraulic system, work hydraulic oil or test oil is often used. Do not use kerosene, gasoline, alcohol, steam or other liquids to prevent corrosion of hydraulic components, pipelines, fuel tanks and seals;

3. A filter or screen should be installed on the circuit for cleaning the oil circuit. At the beginning of cleaning, due to the large amount of impurities, an 80 mesh filter can be used, and a 150 mesh or more filter can be used in the later stage of cleaning;

4. During the cleaning process, use a non-metallic hammer to hit the oil pipe, which can be hit continuously or discontinuously to facilitate the removal of attachments in the pipeline;

5. The intermittent operation of the hydraulic pump is beneficial to improve the cleaning effect, and the intermittent time is generally (10-30) min;

6. In order to prevent corrosion caused by external humidity, the hydraulic pump should continue to operate at the end of cleaning until the temperature returns to normal;

7. The cleaning time is generally (48-60) hours, which should be determined according to factors such as the complexity of the system, the filtration accuracy requirements and the degree of pollution;

8. After cleaning, drain the cleaning oil in the loop.