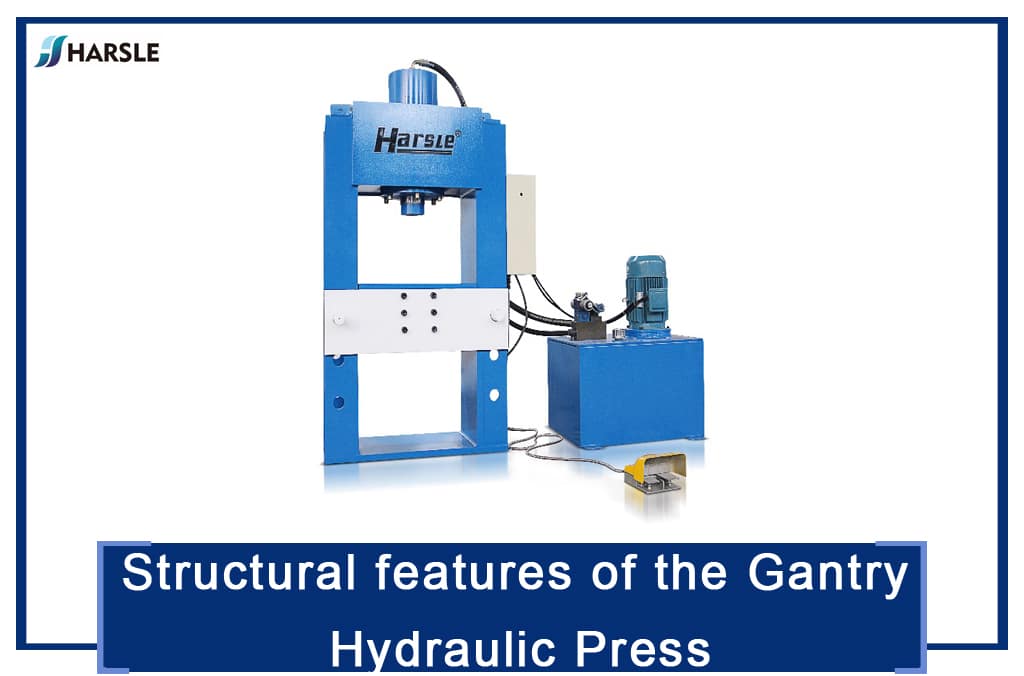

Características estruturais da Prensa Hidráulica Gantry

Hydraulic bush removal tool,HARSLE CNC Machine Tool Co., Ltd. is a professional manufacturer of gantry hydraulic press series products. With more than 20 years of dedicated production and R&D experience, it has unique design and production for gantry hydraulic presses. It can design and manufacture different production process needs for users. Various non-standard gantry hydraulic presses.

HARSLE’s gantry hydraulic press adopts the full-steel structure of the gantry. The vibration aging treatment makes the mechanical deformation small. The frame design is designed by a finite element and has high rigidity and high precision. The gantry hydraulic press table can move up and down, which greatly expands the opening and closing height of the machine and is more convenient to use.

Hydraulic bush removal tool, The gantry hydraulic press is widely used in the dismantling, forming, straightening, stretching and sheet metal forming of the machinery industry, and it can be used as necessary pressure equipment for the modern automobile repair industry. Also used in large and medium-sized motor press-fitting. Provides rotor, stator press, and pressing, calendering, drawing, and forming of large objects.

Gantry hydraulic machine features

1. The control system of this machine is provided with manual operation.

2. The hydraulic system uses an integrated block system.

3. The working pressure and stroke of the machine can be adjusted according to the process requirements within the specified range, and the fixed process can be completed.

4. The hydraulic cylinder of the work surface is pushed and pulled, the loading and unloading operation is convenient, the positioning is accurate, the press-fitting is balanced and reliable.

Gantry hydraulic machine structure

Hydraulic bush removal tool, The equipment is a gantry structure, which is mainly composed of a fuselage, a hydraulic cylinder, a hydraulic system, a power mechanism, an electric system, and a lower workbench. The pipeline and the electrical device are connected to form an overall operation work, and the main part structure is now described. as follows:

1. The fuselage

The fuselage is welded by steel plates, and the vibrations remove the deformation stress. The hydraulic system pumping station is externally installed. “The design is ingenious, the layout is reasonable, and the maintenance is convenient.” The fuel tank is built-in and can be filled with 450 kg of oil, which can be determined according to the oil mark on the fuselage.

The hydraulic cylinder is fixed in the top hole, locked with a screw, and the cap is tight.

2. The master cylinder

This machine is a single-cylinder structure, and the master cylinder is a piston cylinder. The installation form is the flange support of the cylinder mouth, which is fixed in the mounting hole of the upper beam by the lock nut. The cylinder block and the piston rod are made of 45# forgings, wherein the surface of the piston rod is quenched and the hardness is HRC45~52. The surface is plated with hard chrome (the surface is not easily worn). The lower end of the piston rod is threadedly connected to the circular indenter.

Gantry hydraulic system hydraulic system

The hydraulic system consists of the main cylinder, a push-pull cylinder, an oil pump, a control valve, a pipeline, a fuel tank, and various control additional valve components. The control of the electric system drives the piston rod of the cylinder to move up and down to complete various technological actions.